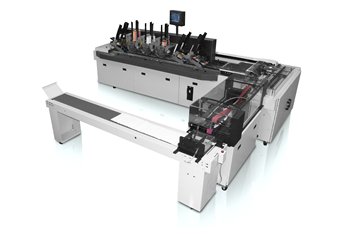

FlowMaster® RS Flex

The FlowMaster RS Flex inserting system delivers high speed (letters up to 16K/hr, flats now up to 12K/hr), superior flexibility and increased productivity with proven servo motor technology. Its rotary and friction feeders can be swapped in 30 minutes

| Overview | Features | Support |

The FlowMaster® RS Flex helps mailers meet SLAs faster by providing unmatched flexibility and automating manual tasks in a one-operator integrated work-cell. The system can also be configured to process letters and flats on the same platform to meet even the most challenging application needs.

Benefits

- Faster flats throughput - Now 25 percent faster, processing up to 12,000 flats per hour

- Boost Machine Efficiency - Selective Sealing reduces machine stoppages and simplifies mail piece repair

- Increase Productivity by 10-15 percent with fast servo-automated setups and adjustments

- Quick change rotary and friction feeders - approximately 30 minutes

- Process virtually any insert material at any given time

- Stop/Start system anywhere/anytime with added operator remote control

- New reporting and networking capabilities - pinpoint opportunities to improve your system and operator performance for maximum uptime

Maximize your overall productivity and flexibility to reduce your cost per mail piece

- Faster flats speed, 12,000/hr do more in less time

- Simplify mail piece repair and system stoppages with Selective Sealing

- Reduce down time between PMs with servo motor technology

- Increase uptime and production with on-screen automation to re-time insertion with the touch of a button

- Reduce Operator Intervention - Outer envelope feeder automatically re-tries feeding, making feed attempts to secure a clean envelope feed before manual intervention is required

- Increase operator productivity with new remote control and tamping deck designed to minimize fatigue and increase efficiency

- Pinpoint new opportunities and evaluate operator performance with reporting and network capabilities

- Fast job setup and changeover time with visual setup markers for common job settings

- Minimize maintenance costs and downtime with proven servo technology

- Reduce material jams and increase system with an enhanced, Teflon-coated paper transport

Rotary Feeder – Flexibility and reliability with suction separation and grid

- Increase material flexibility – single panel glossy, stitched or glued booklets multiple coupons, chromate sheet, onion skin paper and more

- Accurate separation and precise paper control - with gripper arm feeding technology

Friction Feeder – Consistent high speed performance with gap separation

- Material flexibility – CD, Z Folded, business cards, stiff booklets, open ended leading inserts, credit cards and more

- Optimized material delivery - from each separate feeder, based on material type

- Maximized performance of individual feeders – with independently settable material parameters